|

Our Product Range

|

|

|

Home »

Info

Center » End-position cushioning

End-position cushioning

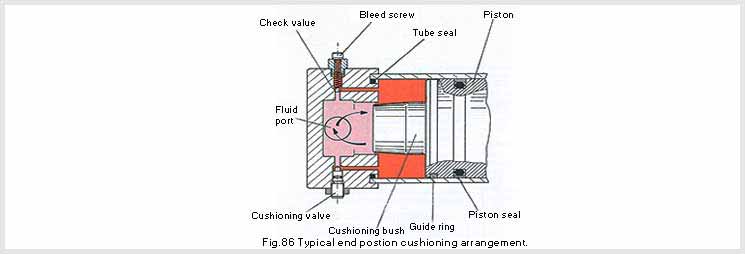

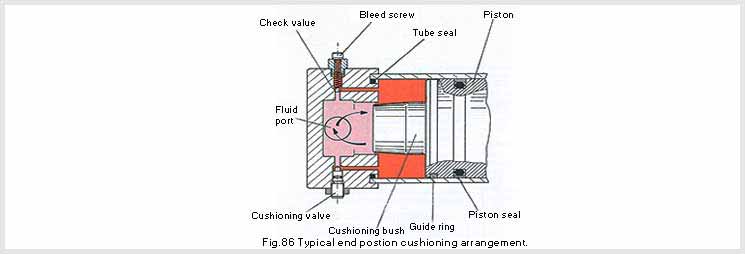

Cushioning, or end-position cushioning,

is a term that refers to the braking and deceleration of final stroke

portion until standstill occurs. End-position Cushioning is required above a

certain stroke speed. The kinetic energy released on impact at the stroke

end must be absorbed by the stroke limit-stops, which are built into the end

caps. Their capacity to absorb this energy depends on the elasticity of the

material. Hydraulic braking function or end-position cushioning must

therefore be applied where piston speeds (v) exceed 0.1 m/sec. The figure

given below, shows a cross-section of the end-position cushioning mechanism

of the end cap.

The piston is fitted with a tapered cushioning bush which when enters into

the bore of the end cap during the final part of the stroke, the main fluid

exit begins to shut until it finally closes off. This is the first stage of

exit-flow throttling, which causes an initial speed deceleration. The

remaining fluid must now exhaust through the cushioning valve. The degree of

cushioning and second stage speed control can be regulated at the cushioning

valve (flow control valve).

A check valve is fitted to achieve fast and full force brake-away from the

end position. A bleed screw may also be built into the check valve. Some

manufacturers have separate bleed screws available as a option. It is

essential that the bleed screw are mounted uppermost.