|

Our Product Range

|

|

|

Home »

Info

Center » Classification of the Pumps

Classification of the Pumps

Industrial hydraulic pumps can be

manufactured in a variety of shapes, sizes, and pumping mechanisms, and are

almost without exception of the "positive displacement" type. This

implies that the outlet is completely sealed from the inlet. Thus,

theoretically, all the hydraulic fluid which is drawn into the pump must be

discharged through the outlet. However, some minor quantities of fluid are

lost because of clearance gaps and internal lubrication channels. Hence, a

worn pump is less efficient than a well maintained or new pump.

The pumps are basically classified according to the pumping mechanism. Some

of the common types include the following:

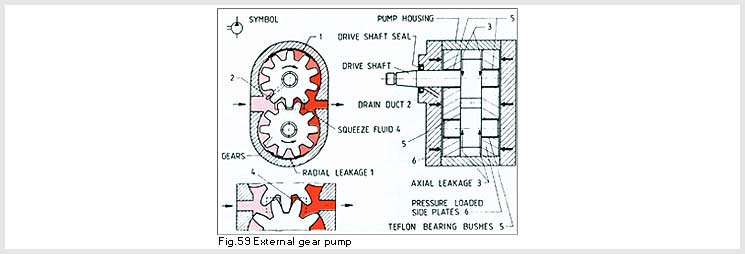

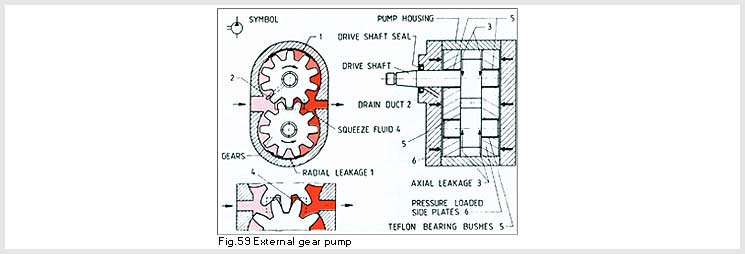

External Gear Pumps

A gear pump consists of a pump housing in which a pair of precisely meshing

gears run with minimal radial and axial clearance. The external gear pumps

works on the principle of using two rotating gears which disengages at the

suction side of the pump, which creates voids allowing atmospheric pressure

to force fluid into the pump. Fluid is pumped out along the outer perimeter

of the housing to the discharge side, and the gears mesh at the center to

discharge the fluid. The gears are supported by bearings on both sides,

which allows high discharge pressure capabilities.

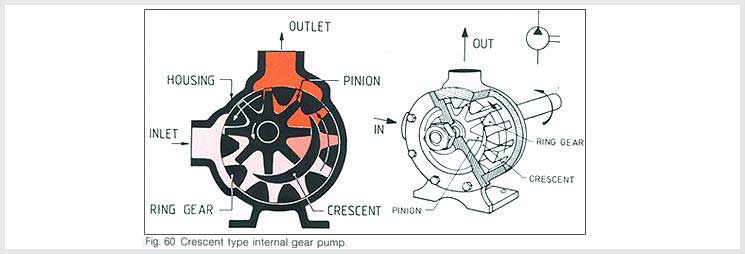

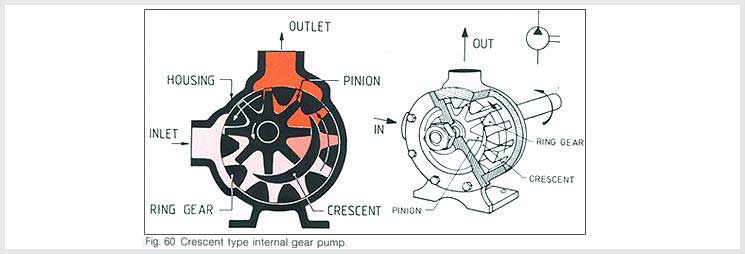

Crescent Type Internal Gear Pump

This type pump is gaining increasing popularity as a high-pressure,

low-noise pump suitable for a variety of hydraulic fluids. It is

comparatively smaller than the external gear pump for the same flow

displacement conditions. The pump shaft drives the pinion which facilitates

the movement of internal ring gear (rotor). As with external gear pumps, the

fluid fills the cavities (voids) formed by the rotating teeth and the

stationary crescent. Both the outer gear and the pinion functions to

transport fluid through the pump.

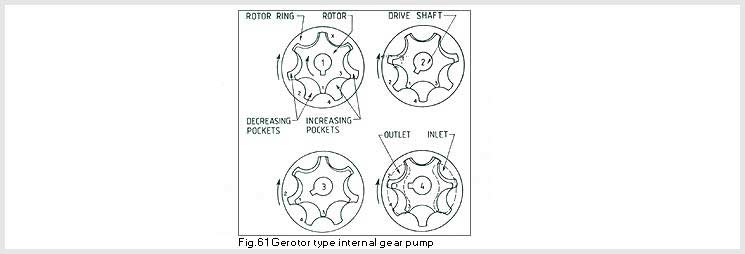

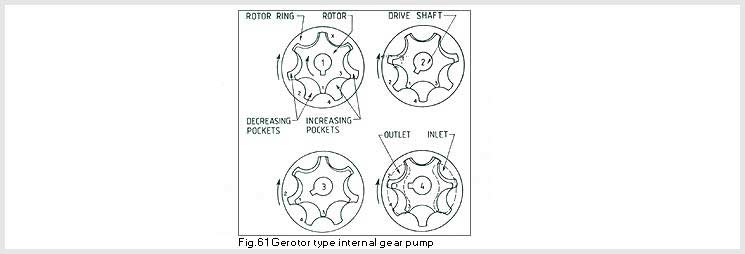

Gerotor type internal gear pump

The gerotor pumps works in a similar manner to the crescent pump. The pump

shaft is also keyed to the inner rotor and both rotor and rotor ring rotate

in the same direction. The tooth count of the inner is one less than rotor

ring. The arrangement forms pumping cavities. Whilst the rotors turn

clockwise , pumping cavities are gradually opening up on the pump inlet side

until they reach point X and then decrease their volume gradually as they

rotate toward the outlet side. The tips of the inner rotor come in contact

with the outer rotor ring to seal the pumping pockets.

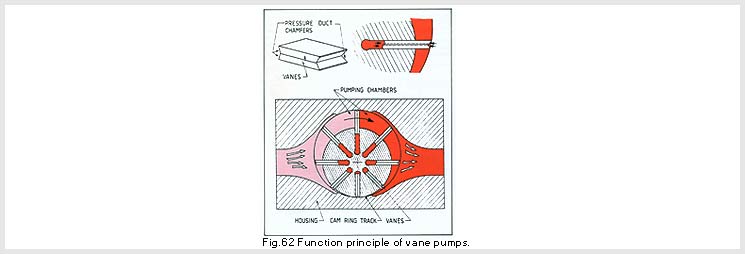

Fixed displacement vane pump (unbalanced)

In Fixed Displacement Vane Pumps, an eccentrically arranged slotted rotor

with movable vanes inserted into the slots rotates within a circular track.

These pumps are said to be “unbalanced", as all the pressure

exposed pumping cavities are situated on one side of the rotor. This

imbalance causes the drive shaft bearing to wear prematurely in specific

conditions where the pump is used above its pressure rating.

Fixed Displacement Vane Pump

(balanced)

Balanced vane pumps use an elliptical track ring instead of the circular

track housing, which permits the use of two sets of intake and outlet ports.

The diametrically opposed pump outlet openings cancel out the radial

pressure loading on the rotor shaft bearing. To improve sealing between the

vane tip and the elliptical track, pressure from the high pressure outlet is

applied to the underside of the vanes

Variable displacement Vane Pump

In these pumps, the heavy pressure control spring forces the movable

circular track ring into the extreme right hand position which is maximum

eccentric position. As the maximum "throw" position can be

adjusted, the maximum pumping capacity of this pump is also adjustable. The

spring force is opposed by the pressure arising from workload resistance.

Thus, when peak pressure has been reached, the pressure control with its

spring decreases the flow from the pump.

Piston pumps

Piston pumps are the high performance

pumps generally used in industrial and mobile hydraulics. The radial design

of the piston pumps enable it to handle a high pressures up to 65 Mpa.

Generally, piston pumps are "loafing" at such low pressures, and

with modern design, piston pumps often reach an overall efficiency of 95% or

even more.

Swash Plate Axial Piston Pump (fixed or variable displacement)

Swash plates pump have a rotating

cylinder containing pistons. A spring pushes the pistons against a

stationary swash plate, which sits at an angle to the cylinder. As the

cylinder block rotates, the piston shoes (slippers) follow the stationary

(non-rotating) swash plate, causing the pistons to reciprocate. The

retracting pistons move past the inlet port slot thus drawing fluid into the

expanding pumping chambers. As the cylinder block rotates further, the

pistons are forced back into the cylinder block and while moving past the

outlet port slot, they force the fluid into the system.

Bent axis piston pump (variable or fixed displacement)

In the bent axis piston pump, the

cylinder block rotates at an offset angle to the drive shaft. The piston

rods are attached to the drive shaft flange by means of ball joints. The

pistons draw fluid into the cylinder bores as they rotate past the inlet

port slot. Pump displacement varies with the offset angle. With the angle of

the fixed displacement pumps being set around 25° and for variable

displacement pumps, the cylinder block may be swiveled around the center

point to adjust the offset angle.

Radial piston pump with thrust ring actuation (variable displacement)

These pumps have a drum-shaped cylinder

block that rotates about a stationary central pintle or valve shaft. The

cylinder block houses the pumping pistons which reciprocate as it rotates.

As the cylinder block rotates, centrifugal force, charging pressure, or

sometimes springs, cause the pistons to follow the inner surface of the cam

ring. The cam ring (thrust ring or reaction ring) together with its support

block are eccentrically movable to adjust the piston stroke and thus the

pump flow.

Radial piston pump (fixed displacement)

These pumps are used for high pressure

application, for example up to 63 Mpa. In such cases, the pistons are

usually moved by an eccentric crankshaft, thus acting radially outwards.

Such pumps may have three or more cylinders, which can have their output

either combined or delivered separately.